Welcome on the homepage of the DFG Research Unit 3022

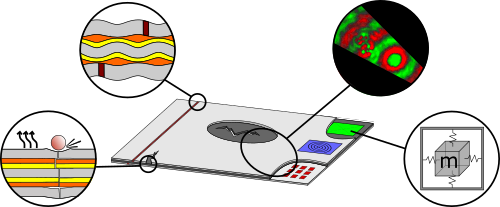

Fibre-metal laminates (FML) have emerged as a promising class of lightweight materials in aerospace and other high-performance industries. To ensure their reliability and safety, this DFG Research Unit explores new strategies for structural health monitoring (SHM), focusing on damage detection and non-destructive testing (NDT). Drawing on advanced ultrasonic sensing techniques, the Research Unit integrates embedded sensors within FML structures, enabling real-time assessment of internal integrity. By uniting expertise across four subprojects, it aims to establish robust, scalable methods for monitoring FML components under realistic service conditions.

Motivation

Conventional inspection routines often fail to capture the complexities of fibre-metal laminates, where material interfaces can mask early signs of damage. A timely, accurate diagnosis of structural integrity is therefore crucial to prevent unexpected failures and reduce maintenance costs. This Research Unit addresses the need for advanced SHM approaches that can detect and interpret signals hidden beneath metallic and composite layers. By refining non-destructive testing methods with modern sensor technologies, it lays the groundwork for safer, more efficient applications of FML in industry and research.

Objectives

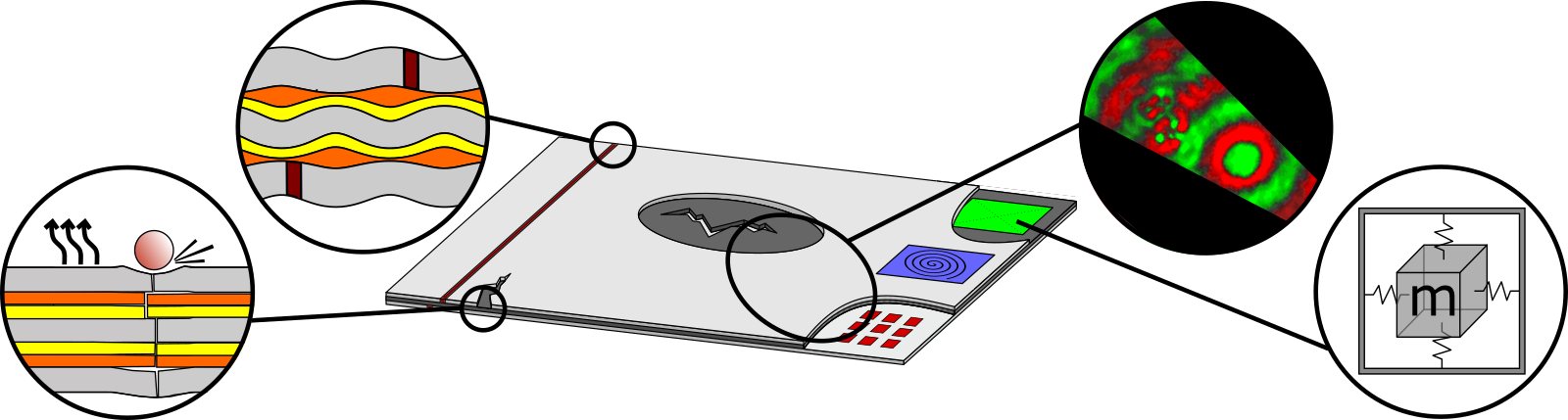

- Objective A (Subproject 1):

Establish how multiple external factors (e.g., temperature, loading) influence wave propagation in FML and develop methods to compensate for these effects in damage detection. - Objective B (Subproject 2):

Design and integrate next-generation sensors—such as multidimensional MEMS devices and phased array transducers—for enhanced in-situ monitoring of fibre-metal laminates. - Objective C (Subproject 3):

Model the interaction of guided ultrasonic waves with material inhomogeneities and splice regions to predict and localize damage under real operating conditions. - Objective D (Subproject 4):

Develop automated, data-driven algorithms that fuse experimental and simulated signals for reliable, real-time identification of damage in FML structures.

Approach

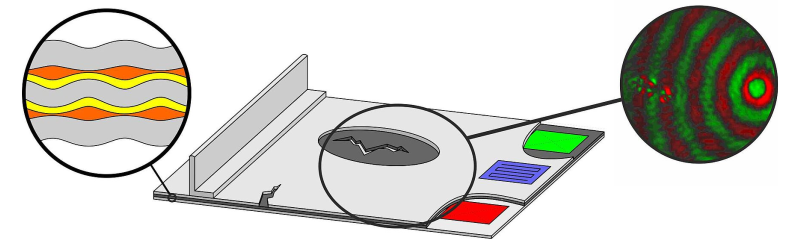

- Wave Propagation Analysis (Subproject 1):

Investigate thermal and mechanical influences on ultrasonic signals in FML, creating correction frameworks that enhance signal clarity for damage detection. - Sensor & Actuator Innovation (Subproject 2):

Embed low-profile MEMS vibrometers and phased array transducers into the laminate, enabling directional emission and multidimensional sensing of structural vibrations. - Multi-Scale Modelling (Subproject 3):

Combine numerical simulations with experimental data to refine models of wave transmission and reflection, accounting for splice zones and diverse laminate architectures. - Intelligent Data Processing (Subproject 4):

Employ machine learning and advanced signal-processing techniques to correlate wave patterns with damage states, delivering automated alerts for timely maintenance.