Effect of inhomogeneities due to large-scale production and damage on wave propagation

Principle Investigators:

- Prof. Dr.-Ing. Christian Hühne, Technische Universität Braunschweig

- PD Dr.-Ing. habil. Natalie Rauter, Helmut-Schmidt-Universität / Universität der Bundeswehr Hamburg

- Prof. Dr.-Ing. habil. Wolfgang Weber, Helmut-Schmidt-Universität / Universität der Bundeswehr Hamburg

Motivation:

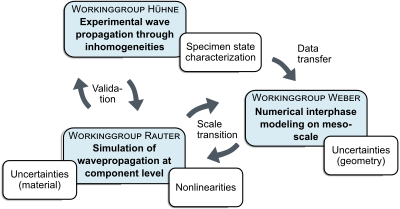

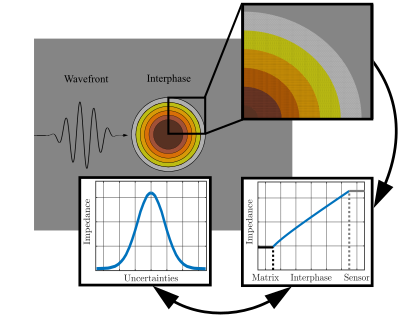

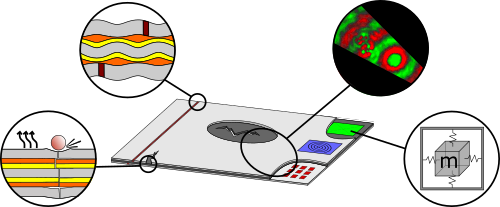

The main objective of this subproject is to evaluate the influence of different design principles and production-induced inhomogeneities on wave propagation in FML through numerical simulation and experimental investigations. Integrating local hybridizations and splices requires increased complexity in the numerical modeling approach, including interphase modeling. Comprehensive validation of numerical models with experimental data is necessary to allow a profound understanding of the GUW propagation in FML and the consequences of structural complexity on damage detection and design of SHM systems for FML.

Aims:

- Investigate the effects of manufacturing and design-induced inhomogeneities on the structural health monitoring of large-scale fiber metal laminates

- Develop and validate advanced 2D and 3D mathematical models for accurately simulating wave propagation under varying inhomogeneity conditions

- Establish a probabilistic multi-scale modeling framework for precisely predicting wave propagation and interaction with geometrical and material-dependent inhomogeneities in FML systems

Approach:

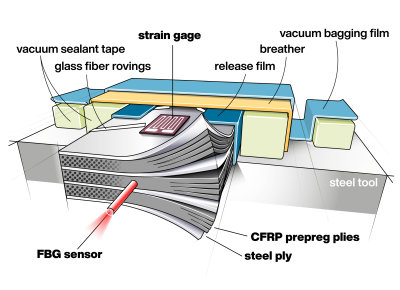

- Manufacturing of structurally complex specimens and characterization of their material and laminate inhomogeneity using experimental measurement methods (e.g. strain gage technique)

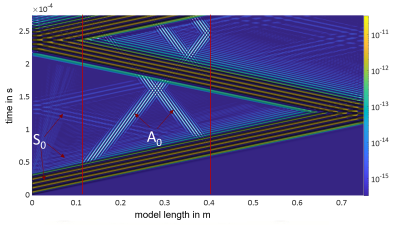

- Measurement and evaluation of the GUW propagation in manufactured inhomogeneous specimens using laser scanning vibrometry

- Development of 2D and 3D numerical models representing the material and structural characteristics of FML to simulate the non-linear wave propagation